Crushed aggregate provide needed bulk to concrete mixes to enable them to harden into materials capable of withstanding immense weight and virtually all forces of nature. Crushed aggregate accounts for approximately 60 to 75 percent of the volume of properties of the mix.

Those particles that are predominantly retained on the 4.75 mm (No. 4) sieve and will pass through 3-inch screen, are called Coarse Aggregatescoarse aggregate. The coarser the aggregate, the more economical the mix. Larger pieces offer less surface area of the particles than an equivalent volume of small pieces. Use of the largest permissible maximum size of coarse aggregate permits a reduction in cement and water requirements. Using aggregates larger than the maximum size of coarse aggregates permitted can result in interlock and form arches or obstructions within a concrete form.

Those particles passing the 9.5 mm (3/8 in.) sieve, almost entirely passing the 4.75 mm (No. 4) sieve, and predominantly retained on the 75 µm (No. 200) sieve are called fine aggregate. For increased workability and for economy as reflected by use of less cement, the fine aggregate should have a rounded shape. The purpose of the fine aggregate is to fill the voids in the coarse aggregate and to act as a workability agent. That allows the area below to become a void, or at best, to become filled with finer particles of sand and cement only and results in a weakened area.

Construction is one of the most competitive business form in this contemporary age. Quality and cost of construction both has to be maintained in this domain. b-Easy is well aware all this essential point and guarantees its esteemed clients to supply only the finest quality of building materials. Brilliant quality of mSand, both air-washed and water-washed mSand that we supply is a perfect approval here. Immense river mining have reduced the availability of river sands for construction. Eventually, genius human brains has found its alternative through mSand (manufacturing sand) or commonly known as robo sand. This type of building material for construction is considered for its higher cohesion and compressive strength mostly used in concreting and brickwork. No wonder, when you get to obtain its first rate quality from b-Easy you can remain assured of equipping your proposed project with reliability and durability benefits.

Proper selection of sands and coarse materials is a must for any sorts of building and construction. If it doesn't gets conducted effectively and efficiently, then, there are several aftermaths that would remain intact with the constructed structure. By availing first rate plastering mSand from b-Easy all these can be avoided with confidence. This is a reputed building material widely used for is used for concrete mixing and enhancing its compressive strength. Requirements related with constructive plastering and flooring works also gets well executed with it. With our user friendly app, all these features and various other advantageous aspects for first rate pSand and water-washed pSand can be acquired with ease. However, river sand and pSand are also reputed for acquiring somewhat similar characteristic properties. Here are some of the crucial differentiating points in between the two.

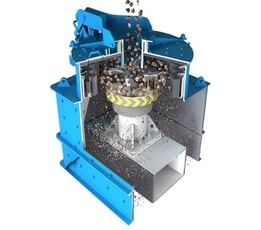

VSI sand making machine is a new type of sand making equipment in sand industry,with exploitation of domestic mines, the production out of the sand and gravel aggregate requirements have gradually improved, the old machine can not meet the needs of the market gradually, VSI series of high vertical shaft impact crusher is SBM experts working conditions combined with China's latest design achievements, is the exclusive domestic production of high performance sand making equipment with world advanced level. The sand making machine is designed for highway, railway, high-rise buildings, municipal, hydroelectric dam construction, concrete mixing stations to provide quality sand and gravel aggregate, artificial sand and stone shaping field device of choice.